TT250 Swingarm Maintenance Tutorial

This TT250 maintenance tutorial addresses swingarm maintenance. There’s not a lot you need to do to maintain your TT250 swingarm. We wanted to take the swingarm off the motorcycle to take a look at the swingarm mounting system and its internals. We found that by greasing the swingarm and shock absorber pivot points, the suspension was noticeably smoother. The bike we performed this on has seen quite a few hard miles off road in dusty environments.

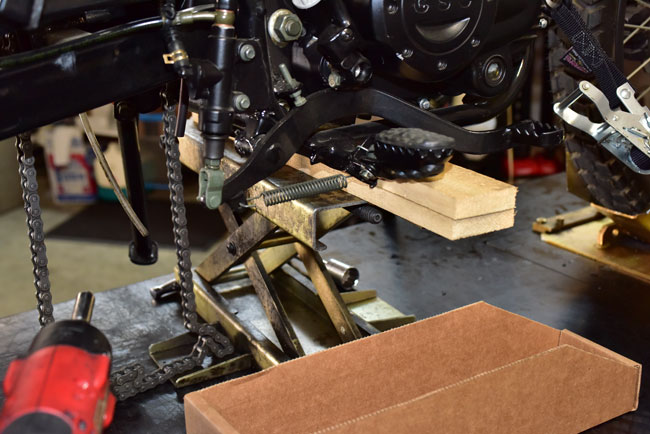

The first step is to safely elevate the rear end of the motorcycle. We use a motorcycle jack; any suitable lift method will work.

-

Remove the rear wheel. Rear wheel removal is covered in the TT250 rear wheel removal tutorial.

-

Detach the rear brake line keepers from the swingarm.

-

-

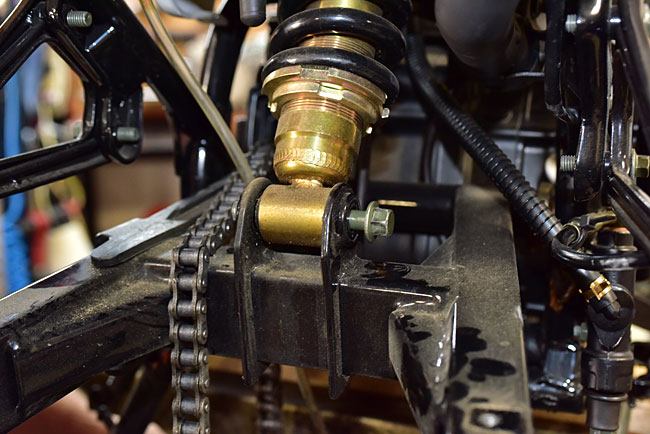

Remove the nut and bolt that attaches the rear shock absorber to the swingarm.

-

-

Rotate the lower portion of the rear shock absorber to clear the swingarm mounting bracket, and remove the bushing from the rear shock absorber.

-

Unbolt the nuts securing the swingarm pivot axle.

-

There will be dust caps/washers on the frame between the swingarm axle nuts and the frame. Remove these and set them aside.

-

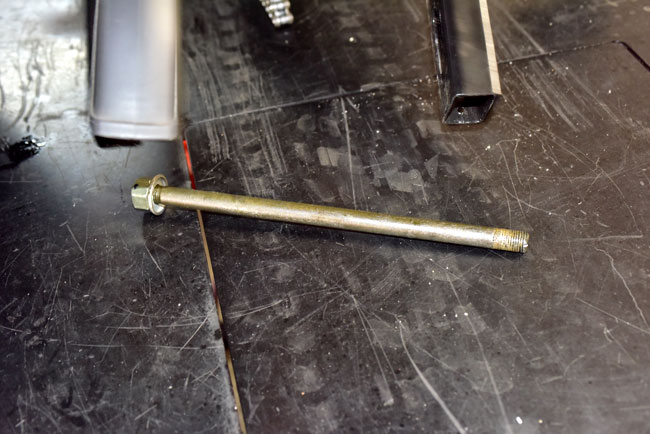

Pull the swingarm pivot axle out of the frame.

-

Remove the swingarm from the motorcycle frame.

-

Remove the dust caps that fit between the frame and the swingarm.

-

-

The next steps involve re-greasing (lubricating) the swingarm pivot points. We use Maxima waterproof grease, which is a great lubricant. We stock the full line of Maxima lubricating oils and grease. Please call us at (800) 884-4173 if you need any of these items.

-

Apply grease to the frame bushings through which the swingarm pivot axle will pass.

-

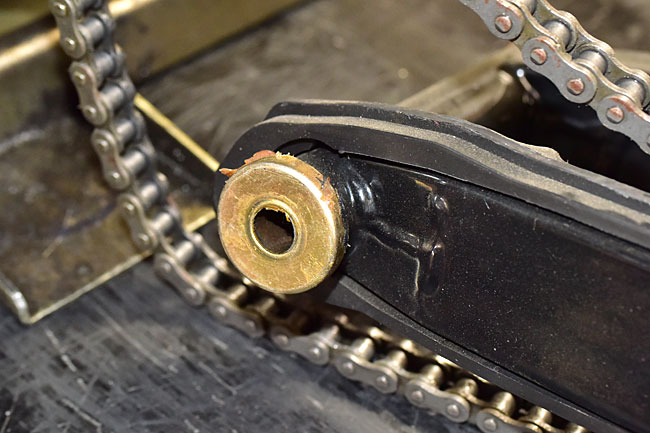

Apply grease to the exterior of the swingarm bushings.

-

Apply grease to the rear shock absorber bushing.

-

Insert the rear shock absorber bushing and apply grease to the exterior exposed edge of the bushing.

-

Assembly is the reverse of disassembly. Torque the shock absorber nut and bolt to 35 N-m. There is no torque specification for the swingarm pivot axle nuts. Tighten the swingarm pivot axle nuts equally such that there is no side-to-side play in the swingarm and it pivots up and down with minimal drag.