RX4 VALVE ADJUSTMENT

RX4 Valve Adjustment Tutorial

This tutorial addresses how to adjust the RX4’s valves.

General Information

Procedure

Allow the motorcycle to cool completely such that the engine is at room temperature.

Insert the ignition key in the left side panel and remove the rear seat.

Remove the two 8mm bolts securing the front seat and remove the front seat.

Remove the two 8mm bolts at the rear of the fuel tank.

Similarly remove the right body panel from the motorcycle.

Remove the four 5mm Allen bolts securing the fuel tank upper body panel.

Remove the motorcycle fuel tank upper body panel.

Remove the 5mm Allen bolts at the rear of the left and right lower fuel tank body panels.

Remove the two 5mm Allen bolts at the front of the fuel tank.

Remove the 3mm Allen bolts from the front of the left and right forward body panels.

Remove the Phillips-head screws beneath the forward portion of the left and right forward body panels.

Drape a cloth over the right motorcycle engine guards to prevent scratching the forward body panels during removal.

Remove the forward body panels.

Disconnect the electrical connector from the right forward panel.

At this point, the fuel tank can be rotated up and away from the engine without disconnecting any of the fuel hoses or electrical wires. Use narrow web straps or rope to secure the fuel tank on both the left and right sides as shown below. The straps or rope attach to the fuel tank panel mount near the front of the fuel tank and the passenger foot peg bracket. Lift the fuel tank up at the rear and remove the rubber biscuit. Insert a cloth behind the fuel tank to prevent scratching the fuel tank. Shift the fuel tank about an inch to the rear and allow it rest on the cloth. Tighten the straps or rope to secure the fuel tank as shown below to provide access to the engine valve cover.

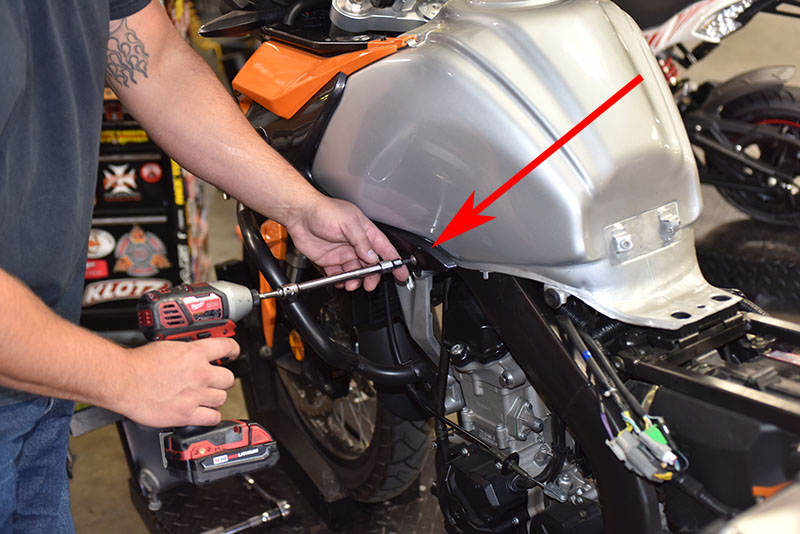

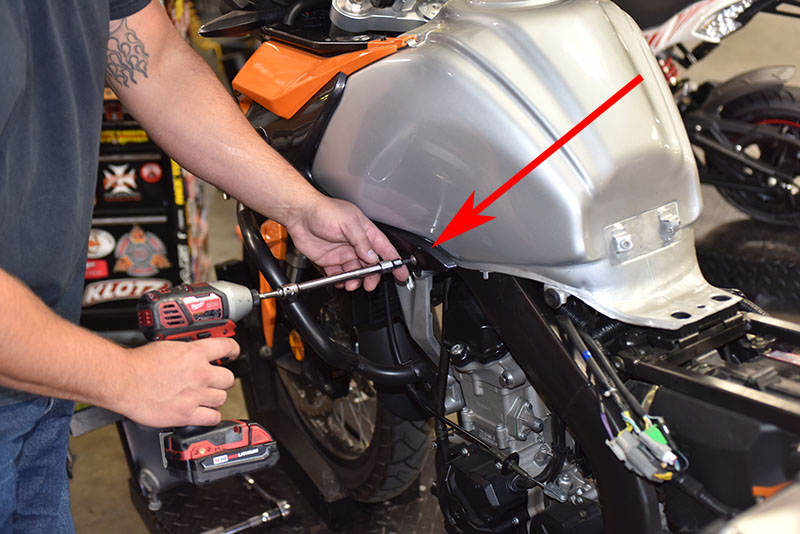

Remove the 8mm Allen bolts securing the upper two attach points on the left engine guard mounting bracket, and the 13mm bolt on the lower attach point on the left engine guard mounting bracket, as shown below. These are long bolts and they will probably have to be driven out from the right side of the motorcycle.

Disconnect the crankcase breather hose from the left side of the engine.

Remove the four 5mm Allen bolts securing the valve cover to the cylinder head.

Gently and carefully remove the valve cover from the engine, sliding it out from the left side of the motorcycle, taking care not to damage the valve cover seal.

Remove the spark plug lead and the spark plug.

Remove the access port on the left side of the engine crankcase with a 10mm Allen wrench.

Remove the engine view port cover with a 6mm Allen wrench from the lower left front of the engine crankcase.

At this point, make sure the motorcycle is in neutral and bring the engine to top dead center. The way to do this is to insert a 10mm Allen wrench in the engine drive port and rotate the engine counterclockwise as viewed from the left side of the engine.

Observe the intake valve rocker on top of the engine as you do so (it is the rocker at the rear of the cylinder head).

As soon as the intake valve rocker actuates and then releases the intake valve, observe the engine view port at the lower left front the engine (you may need a flashlight to see inside the viewport). Continue to rotate the engine slowly a few more degrees. A scribe line will come into view with a “T” oriented horizontally below the scribe line. When the scribe line is aligned with the marker in the viewport, the engine is at top dead center.

As you do this, the engine will rotate a few degrees on its own as you rotate the crankshaft with the 10mm drive. It will feel as if it is going past the compression point, but the engine is not experiencing compression because the spark plug has been removed. This self-induced engine rotation is caused by the valve springs and rockers acting on the camshaft. You can rotate the engine clockwise or counterclockwise, as necessary, to bring the scribe line into alignment with the marker as shown above.

When the engine is at top dead center as outlined above, adjust the valve gap to 0.06mm for the intake valves, and 0.08mm for the exhaust valves. This is done by:

Take care when adjusting the threaded adjustor to not drive the valve open by screwing the adjustor in too far.

The valve adjustment is shown in the photo below. The upper arrow points to the screwdriver used to the turn the adjustor. The middle arrow points to the 8mm wrench used to turn the locknut. The lower arrow points to the feeler gage.

CSC has found that inserting feeler gages of the appropriate thickness at both valve locations while making the adjustment (i.e., both intake valves, and after the intake valve gap adjustment, both exhaust valves) makes for more accurate and consistent gap adjustments. You can see this in the photo below.

Note that the valve gaps recommended here are slightly larger than recommended by Zongshen (Zongshen recommends 0.04mm for the intake gap and 0.06mm for the exhaust gap). We have found the motorcycle runs better with the gaps set at 0.06mm for the intake gap and 0.08mm for the exhaust gap.

The photos above show adjusting the valve gaps for the intake valves. After completing the intake gap adjustments, make the adjustments for the exhaust valves.

After completing the adjustment, use the 10mm Allen drive to rotate the engine through two complete engine revolutions and check the gaps again to make sure the adjustments are correct.

After adjusting the valves, reassemble the motorcycle (assembly is the reverse of disassembly).

Components and Parts

No parts are required for making the valve adjustment. As outlined above, several tools and feeler gages are necessary. CSC Motorcycles stocks tool kits and feeler gages. Please call us at (800) 884-4173 for any needs.

This tutorial addresses how to adjust the RX4’s valves.

General Information

- The RX4 has a high performance, single overhead cam, 4-valve engine. There are two exhaust valves and two intake valves. The engine’s single camshaft has two lobes that actuate two rocker arms. One rocker arm actuates both intake valves; the other rocker arm actuates both exhaust valves.When the engine is at the top of its compression stroke (at top dead center), all valves are closed.

- Thermal expansion occurs as engine temperature increases during normal operation. In order to compensate for this thermal expansion, there is a gap in the cam lobe/rocker arm/valve train (referred to as valve gap). As the engine warms, this gap approaches zero.

- As the valve impacts the valve seat repeatedly during normal operation, microscopic deformation occurs in both the valve and the valve seat. This deformation grows over time as the engine runs. As the deformation increases, it reduces the valve gap (i.e., the clearance built into the valve train to account for thermal expansion). Over time, the valve gradually moves higher into the cylinder head and the valve gap decreases. If the valve gap decreases beyond acceptable limits, it will result in the valve being held off the valve seat when the valve is supposed to be closed. This greatly reduces heat transfer from the valve to the cylinder head, the valve temperature increases, and the valve will be damaged.Inadequate valve gap also makes the engine harder to start.Valve gap adjustment keeps the valve gap within acceptable limits.

- The RX4 engine uses a threaded adjustor shaft with a lock nut to set and lock the valve gap. These adjustors are located in the ends of the rocker arms that interface directly with the valve stem.

- The RX4 valve adjustment procedure consists of several actions, including gaining access to the valve rocker arms and their adjustment screws, rotating the engine to top dead center such that the valves are closed, loosening the threaded adjustor lock nuts, setting the valve gaps to the specified gap, tightening the lock nuts to lock the threaded adjustors at this gap, and then reassembling the motorcycle.

- Most of the work in adjusting the valves is associated with gaining access to the adjustors. The adjustment operation (once the valve train is accessed) takes only a few minutes.

- Valve adjustment requires a cold engine. Allow your motorcycle to cool completely before adjusting the valves.

- The valves should be adjusted every 5,000 miles.

- The valve gap should be set at 0.06mm for the intake valves, and 0.08mm for the exhaust valves.

- Tools required for adjusting the valves include feeler gages, an 8mm socket, an 8mm wrench, a 3mm Allen wrench, a 5mm Allen wrench, a 6mm Allen wrench, an 8mm Allen wrench, a 10mm Allen wrench, a 13mm socket, a Phillips-head screw driver, a flat blade screw driver, web straps or rope, a pair of pliers, a spark plug wrench, and a flashlight.

Procedure

Allow the motorcycle to cool completely such that the engine is at room temperature.

Insert the ignition key in the left side panel and remove the rear seat.

Remove the two 8mm bolts securing the front seat and remove the front seat.

Remove the two 8mm bolts at the rear of the fuel tank.

Similarly remove the right body panel from the motorcycle.

Remove the four 5mm Allen bolts securing the fuel tank upper body panel.

Remove the motorcycle fuel tank upper body panel.

Remove the 5mm Allen bolts at the rear of the left and right lower fuel tank body panels.

Remove the two 5mm Allen bolts at the front of the fuel tank.

Remove the 3mm Allen bolts from the front of the left and right forward body panels.

Remove the Phillips-head screws beneath the forward portion of the left and right forward body panels.

Drape a cloth over the right motorcycle engine guards to prevent scratching the forward body panels during removal.

Remove the forward body panels.

Disconnect the electrical connector from the right forward panel.

At this point, the fuel tank can be rotated up and away from the engine without disconnecting any of the fuel hoses or electrical wires. Use narrow web straps or rope to secure the fuel tank on both the left and right sides as shown below. The straps or rope attach to the fuel tank panel mount near the front of the fuel tank and the passenger foot peg bracket. Lift the fuel tank up at the rear and remove the rubber biscuit. Insert a cloth behind the fuel tank to prevent scratching the fuel tank. Shift the fuel tank about an inch to the rear and allow it rest on the cloth. Tighten the straps or rope to secure the fuel tank as shown below to provide access to the engine valve cover.

Remove the 8mm Allen bolts securing the upper two attach points on the left engine guard mounting bracket, and the 13mm bolt on the lower attach point on the left engine guard mounting bracket, as shown below. These are long bolts and they will probably have to be driven out from the right side of the motorcycle.

Disconnect the crankcase breather hose from the left side of the engine.

Remove the four 5mm Allen bolts securing the valve cover to the cylinder head.

Gently and carefully remove the valve cover from the engine, sliding it out from the left side of the motorcycle, taking care not to damage the valve cover seal.

Remove the spark plug lead and the spark plug.

Remove the access port on the left side of the engine crankcase with a 10mm Allen wrench.

Remove the engine view port cover with a 6mm Allen wrench from the lower left front of the engine crankcase.

At this point, make sure the motorcycle is in neutral and bring the engine to top dead center. The way to do this is to insert a 10mm Allen wrench in the engine drive port and rotate the engine counterclockwise as viewed from the left side of the engine.

Observe the intake valve rocker on top of the engine as you do so (it is the rocker at the rear of the cylinder head).

As soon as the intake valve rocker actuates and then releases the intake valve, observe the engine view port at the lower left front the engine (you may need a flashlight to see inside the viewport). Continue to rotate the engine slowly a few more degrees. A scribe line will come into view with a “T” oriented horizontally below the scribe line. When the scribe line is aligned with the marker in the viewport, the engine is at top dead center.

As you do this, the engine will rotate a few degrees on its own as you rotate the crankshaft with the 10mm drive. It will feel as if it is going past the compression point, but the engine is not experiencing compression because the spark plug has been removed. This self-induced engine rotation is caused by the valve springs and rockers acting on the camshaft. You can rotate the engine clockwise or counterclockwise, as necessary, to bring the scribe line into alignment with the marker as shown above.

When the engine is at top dead center as outlined above, adjust the valve gap to 0.06mm for the intake valves, and 0.08mm for the exhaust valves. This is done by:

- Loosening the locknut on the valve adjustor.

- Backing the adjustor out with a screwdriver.

- Inserting the feeler gage between the bottom of the adjuster and the top of the valve stem.

- Moving the adjustor in with the screwdriver to contact with the feeler gage shim.

- Tightening the locknut.

Take care when adjusting the threaded adjustor to not drive the valve open by screwing the adjustor in too far.

The valve adjustment is shown in the photo below. The upper arrow points to the screwdriver used to the turn the adjustor. The middle arrow points to the 8mm wrench used to turn the locknut. The lower arrow points to the feeler gage.

CSC has found that inserting feeler gages of the appropriate thickness at both valve locations while making the adjustment (i.e., both intake valves, and after the intake valve gap adjustment, both exhaust valves) makes for more accurate and consistent gap adjustments. You can see this in the photo below.

Note that the valve gaps recommended here are slightly larger than recommended by Zongshen (Zongshen recommends 0.04mm for the intake gap and 0.06mm for the exhaust gap). We have found the motorcycle runs better with the gaps set at 0.06mm for the intake gap and 0.08mm for the exhaust gap.

The photos above show adjusting the valve gaps for the intake valves. After completing the intake gap adjustments, make the adjustments for the exhaust valves.

After completing the adjustment, use the 10mm Allen drive to rotate the engine through two complete engine revolutions and check the gaps again to make sure the adjustments are correct.

After adjusting the valves, reassemble the motorcycle (assembly is the reverse of disassembly).

Components and Parts

No parts are required for making the valve adjustment. As outlined above, several tools and feeler gages are necessary. CSC Motorcycles stocks tool kits and feeler gages. Please call us at (800) 884-4173 for any needs.