RX4 Drive Train Tutorial

General Service Information

- Keep grease and oil off brake pads and rotors

- Discard contaminated brake pads and clean rotors with degreaser

- Brake dust may contain asbestos fibers

- Do not clean brake dust with compressed air

- Do not allow water, dirt or other contaminates to enter the hydraulic brake system

- If brake lever or pedal feels spongy, system needs to be bled.

- Only use fresh DOT 3 or 4 brake fluid from a sealed container

- After servicing wheels, brakes or suspension always verify brake function before riding

- When servicing wheels, suspension or steering, lift motorcycle with suitable work stand

| EMISSION RELATED ITEMS MILES(x)1K | FIRST SERVICE 500 | 2.5K | 5K | 7.5K | 10K | 12.5 | 15K | 17.5 | 20K | |

|---|---|---|---|---|---|---|---|---|---|---|

| FUEL LINE | * | I | I | I | I | I | ||||

| FUEL FILTER | * | R | R | R | R | |||||

| THROTTLE OPERATION | * | I | I | I | I | I | ||||

| AIR CLEANER | I | I | I | I | ||||||

| SPARK PLUG | I | I | R | I | ||||||

| VALVE CLEARANCE | * | I | I | I | I | |||||

| ENGINE OIL | R | R | R | R | R | R | R | R | R | |

| ENGINE OIL FILTER | R | R | R | R | R | R | R | R | R | |

| RADIATOR COOLANT | I | I | R | I | ||||||

| COOLING SYSTEM | * | I | I | I | I | |||||

| EVAPORATIVE EMISSION CONTROL SYSTEM | * | I | |

I | I | I | ||||

| NON-EMISSION RELATED ITEMS MILES(x)1K |

FIRST SERVICE

500

| 2.5K | 5K | 7.5 | 10K | 12.5 | 15K | 17.5 | 20K | |

| DRIVE CHAIN | I | I | I | I | I | I | I | I | I | |

| BATTERY | I | I | I | I | I | I | I | I | I | |

| BRAKE FLUID | I | I | I | I | I | R | I | I | ||

| BRAKE PAD WEAR | I | I | I | I | I | I | I | I | ||

| BRAKE SYSTEM | I | I | I | I | I | |||||

| BRAKE LIGHT SWITCH | * | I | I | I | I | I | ||||

| HEADLIGHT AIM | * | I | I | I | I | I | ||||

| CLUTCH SYSTEM | I | I | I | I | I | |||||

| SIDE STAND | I | I | I | I | I | |||||

| SUSPENSION | * | I | I | I | I | I | ||||

| NUTS, BOLTS, FASTENERS | I | I | I | I | I | I | I | I | I | |

| WHEELS/TIRES | ** | I | I | I | I | I | I | I | I | I |

| STEERING HEAD BEARINGS | ** | I | I | I | I | I |

Specifications

Standard Torque Values

| Bolt Size | Torque |

|---|---|

| 5 mm 6 mm 8 mm 10 mm 12 mm |

5.2 mn (3.8 ft lbs) 10 nm (7 ft lbs) 22 nm (16 ft lbs) 34 nm (25 ft lbs) 54 nm (40 ft lbs) |

Front Wheel

Rim- 2.15 x 19 in

Tire- 110/80R19,

Cold tire pressure- 36 psi

Wheel runout- 2 mm (0.08 in) Axial/Radial

Axle torque- 106 nm (78 ft lbs)

Axle runout- 0.02 mm (0.008 in)

Spoke nipple size- 6 mm

Spoke nipple torque- 3.7 nm (32.7 in lbs)

Rear wheel

Rim- 4.25 x 17 in

Tire- 150/70R17

Cold tire pressure- 36 psi

Wheel runout- 2 mm (0.08 in) Axial/Radial

Axle torque- 106 nm (78 ft lbs)

Axle runout- 0.02 mm (0.008 in)

Spoke nipple size- 6 mm

Spoke nipple torque- 3.7 nm (32.7 in lbs)

Rear Sprocket- 44 teeth

Chain- 530 x 108 links

Drive chain slack- 25-35 mm (1.0-1.4 in)

Front Fork

Stanchion diameter- 41 mm

Suspension travel- 130 mm (5.1in)

Rebound dampening adjustment- 16 clicks

Fork oil weight- 5w suspension fluid

Rear Shock

Eye to eye length- 44 cm (17.3 in)

Suspension travel- 120 mm (4.7 in)

Rebound dampening adjustment- 6 clicks

Damper gas pressure- 150 psi

Front Brake

Minimum pad thickness- 1 mm (wear indicator)

Minimum rotor thickness- 3 mm

Mounting bolt torque- (22 ft lbs)

Brake fluid- DOT 3 or 4

Rear Brake

Minimum pad thickness- 1 mm (wear indicator)

Minimum rotor thickness- 3 mm

Mounting bolt torque- (22 ft lbs)

Brake fluid- DOT 3 or 4

Stanchion diameter- 41 mm

Suspension travel- 130 mm (5.1in)

Rebound dampening adjustment- 16 clicks

Fork oil weight- 5w suspension fluid

Rear Shock

Eye to eye length- 44 cm (17.3 in)

Suspension travel- 120 mm (4.7 in)

Rebound dampening adjustment- 6 clicks

Damper gas pressure- 150 psi

Front Brake

Minimum pad thickness- 1 mm (wear indicator)

Minimum rotor thickness- 3 mm

Mounting bolt torque- (22 ft lbs)

Brake fluid- DOT 3 or 4

Rear Brake

Minimum pad thickness- 1 mm (wear indicator)

Minimum rotor thickness- 3 mm

Mounting bolt torque- (22 ft lbs)

Brake fluid- DOT 3 or 4

Troubleshooting

Hard steering

- Steering stem adjusted to tight

- Damaged steering head bearings

- Inadequate lubrication in steering head bearings

- Low tire pressure

Steers to one side or does not track straight

- Front wheel installed incorrectly

- Misaligned rear wheel

- Loose axle

- Loose front axle pinch bolts

- Worn wheel bearings

- Worn swingarm bearings

- Bent axle

- Bent fork tube

Wheels wobble

- Loose axle

- Loose front axle pinch bolt

- Wheels out of balance

- Faulty tire

- Bent rim

- Bent spokes

- Worn wheel bearings

Brake lever/pedal soft of spongy

- Air in brake hydraulic system

- Leak in hydraulic brake system

- Misadjusted brake lever/pedal

- Worn seals in master cylinder

- Worn seals in caliper

- Clogged passages in brake hydraulic system

- Low fluid

- Contaminated brake pads or rotors

- Warped rotor

- Bent or worn brake lever/pedal

Brakes

TROUBLESHOOTING | BRAKES

If brake lever/pedal soft or spongy, these are possible causes:

Servicing Front and Rear Brakes

To bleed hydraulic system the use of a commercially available brake bleeder is highly recommended.

Replacing Front Pads

Step 1: Place motorcycle on suitable work stand

Step 2: Replace pads one caliper at a time

Step 3: Remove the front caliper mounting bolts

Step 4: With a clean large flat screwdriver spread the brake pads completely apart. This will compress the pistons to make room for the new pads.

Step 5: Remove the brake pad pins and pads

Step 8: Verify caliper locating dowels are in place

Step 6: When installing new pads:

Replacing Rear Pads

Step 1: Place motorcycle on suitable work stand

Step 2: Remove rear caliper mounting bolts and remove caliper

Step 3: With a clean large flat screwdriver spread the brake pads completely apart. This will compress the pistons to make room for the new pads.

Step 4: Remove the brake pad pin cover, pad pin and pads

Step 5: Install new pads in retaining slot on carrier

Step 6: Install caliper over pads and line up mounting bolts. Install front bolt first. Install rear bolt then pad pin.

Step 7: When installing new pads

TROUBLESHOOTING | BRAKES

If brake lever/pedal soft or spongy, these are possible causes:

- Air in brake hydraulic system

- Leak in hydraulic brake system

- Misadjusted brake lever/pedal

- Worn seals in master cylinder

- Worn seals in caliper

- Clogged passages in brake hydraulic system

- Low fluid

- Contaminated brake pads or rotors

- Warped rotor

- Bent or worn brake lever/pedal

Servicing Front and Rear Brakes

- Fluid inspection- When the fluid is low in the master cylinder reservoir, check the brake pads for wear. As the brake pads wear the caliper pistons are pushed out and displaces fluid from the master cylinder.

- If the fluid is low and the pads are not worn check for leaks.

- If the pads are near minimum thickness, replacement is necessary.

- Keep grease and oil off brake pads and rotors

- Discard contaminated brake pads and clean rotors with degreaser

- Brake dust may contain asbestos fibers

- Do not clean brake dust with compressed air

- Do not allow water, dirt or other contaminates to enter the hydraulic brake system

- If brake lever or pedal feels spongy, system needs to be bled.

- Only use fresh DOT 3 or 4 brake fluid from a sealed container

- Always replace brake pads as pairs to unsure even pressure

- After servicing wheels, brakes or suspension always verify brake function before riding

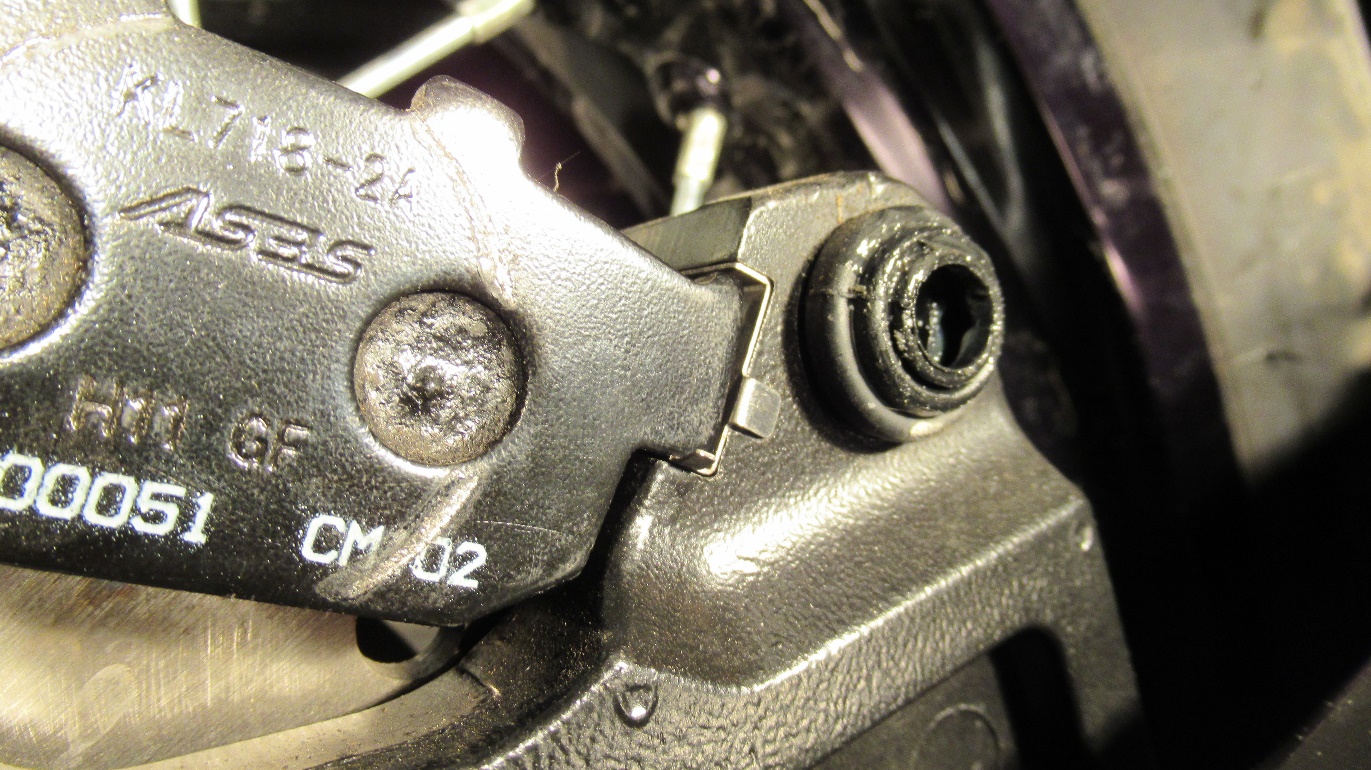

To bleed hydraulic system the use of a commercially available brake bleeder is highly recommended.

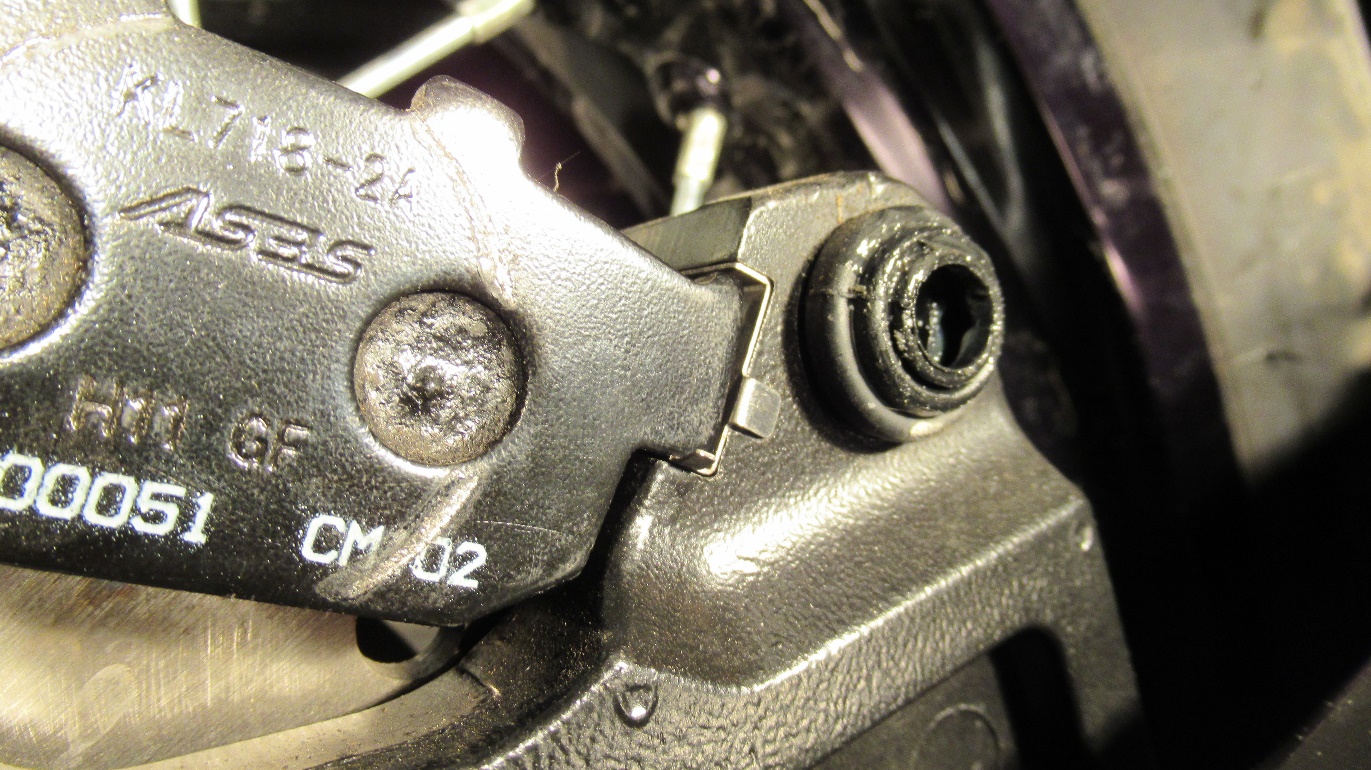

- Connect the brake bleeder to the bleed valve on the caliper

- Position the master cylinder reservoir as level as possible. Position rags to prevent spills. DOT 3 / 4 brake fluid is corrosive and will damage painted surfaces.

- Remove cover and fill master cylinder reservoir

- Activate brake bleeder and loosen the bleed valve. Add fluid to reservoir, do not let fluid run dry.

- Close bleed valve

- Slowly pump up pressure in master cylinder until no air bubbles are seen floating up to the surface in the reservoir

- Perform procedure until the brake fluid is flushed and bleed. Repeat if necessary.

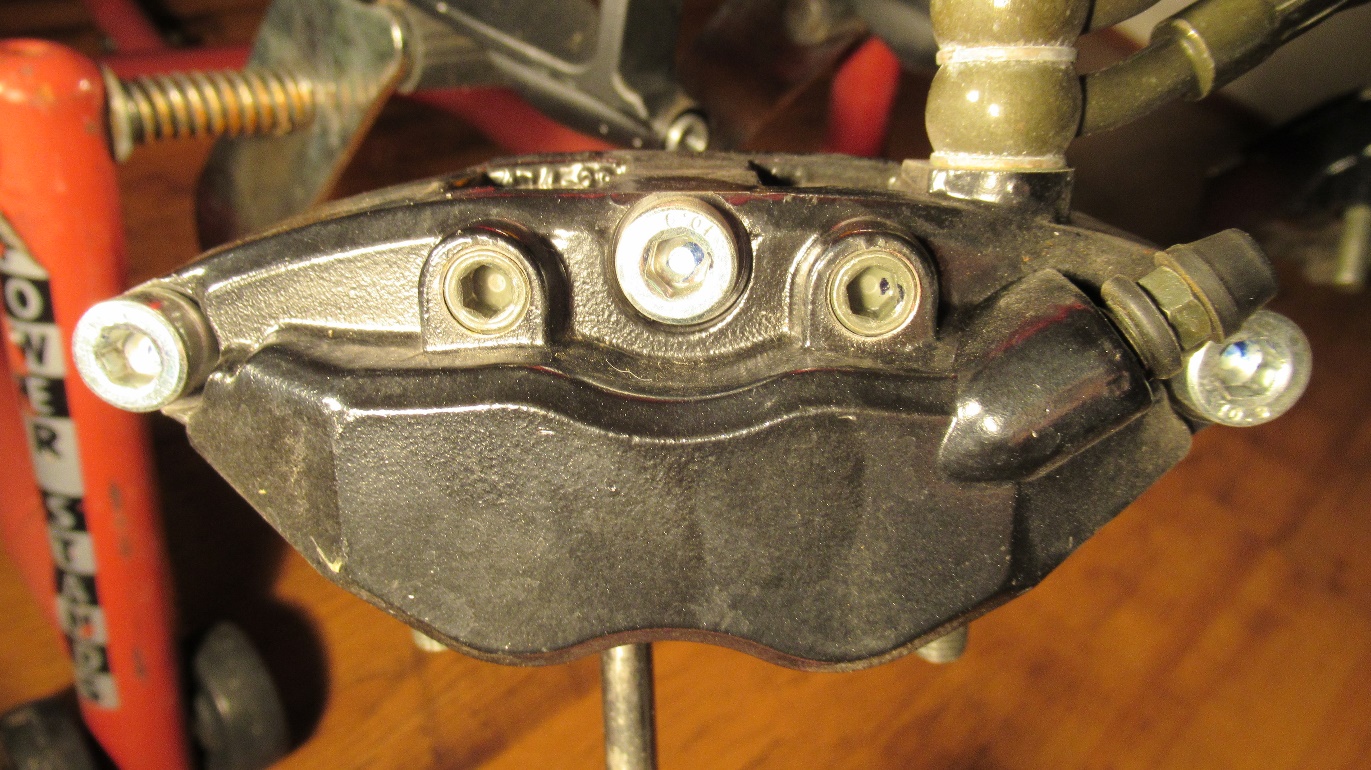

Replacing Front Pads

Step 1: Place motorcycle on suitable work stand

Step 2: Replace pads one caliper at a time

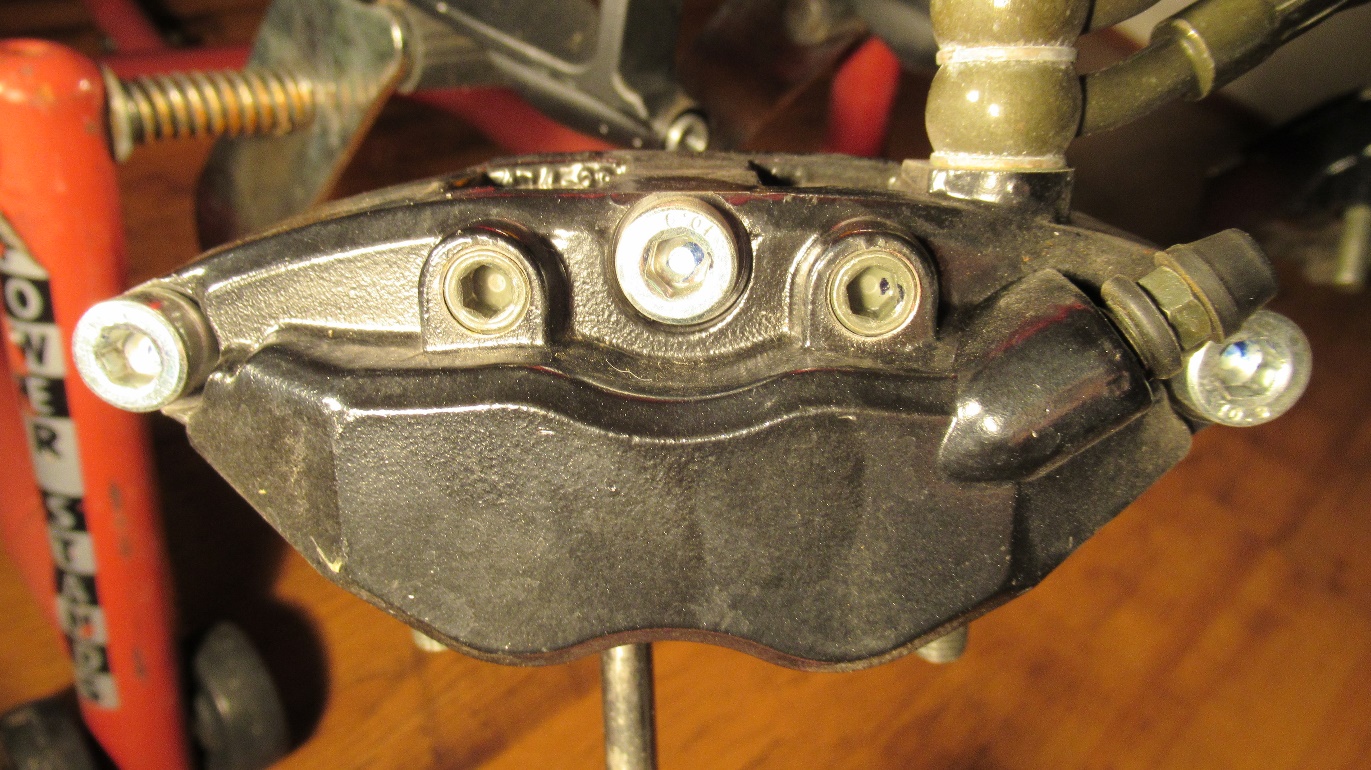

Step 3: Remove the front caliper mounting bolts

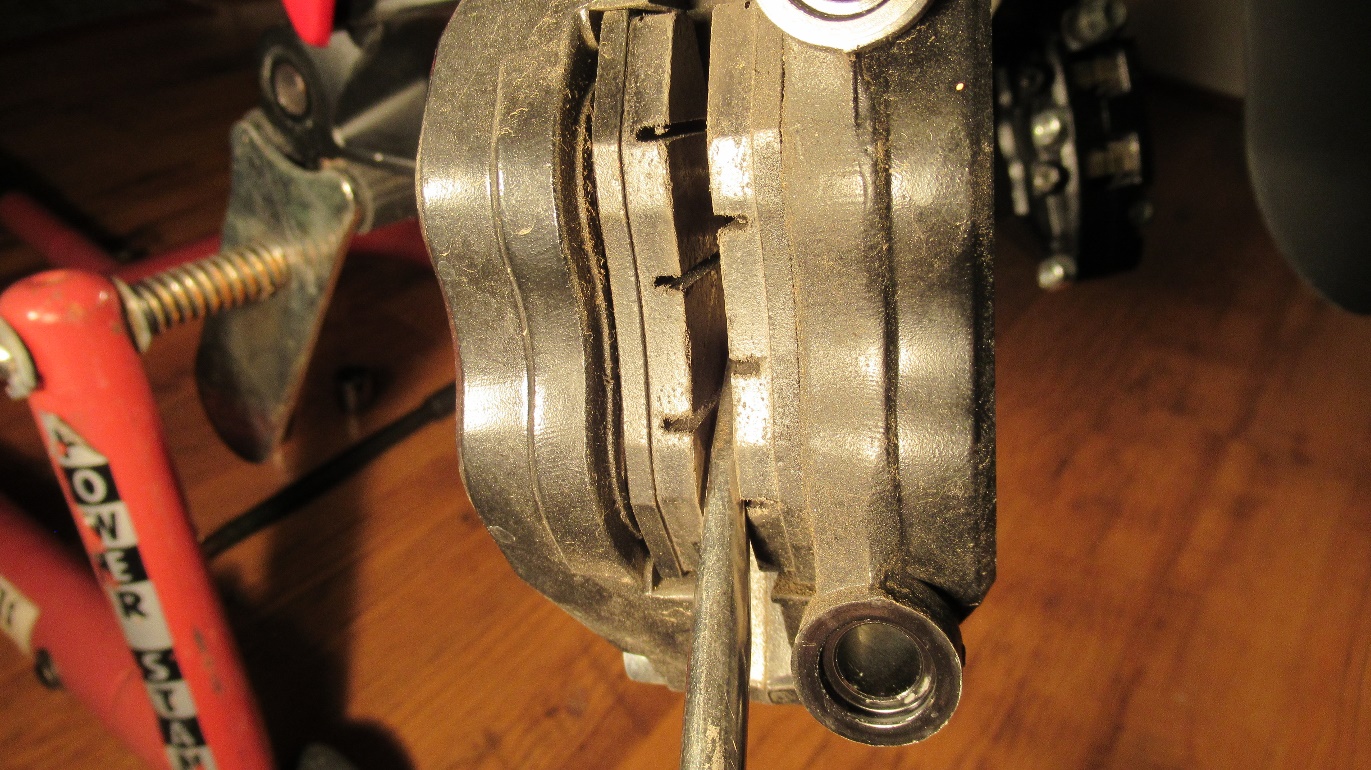

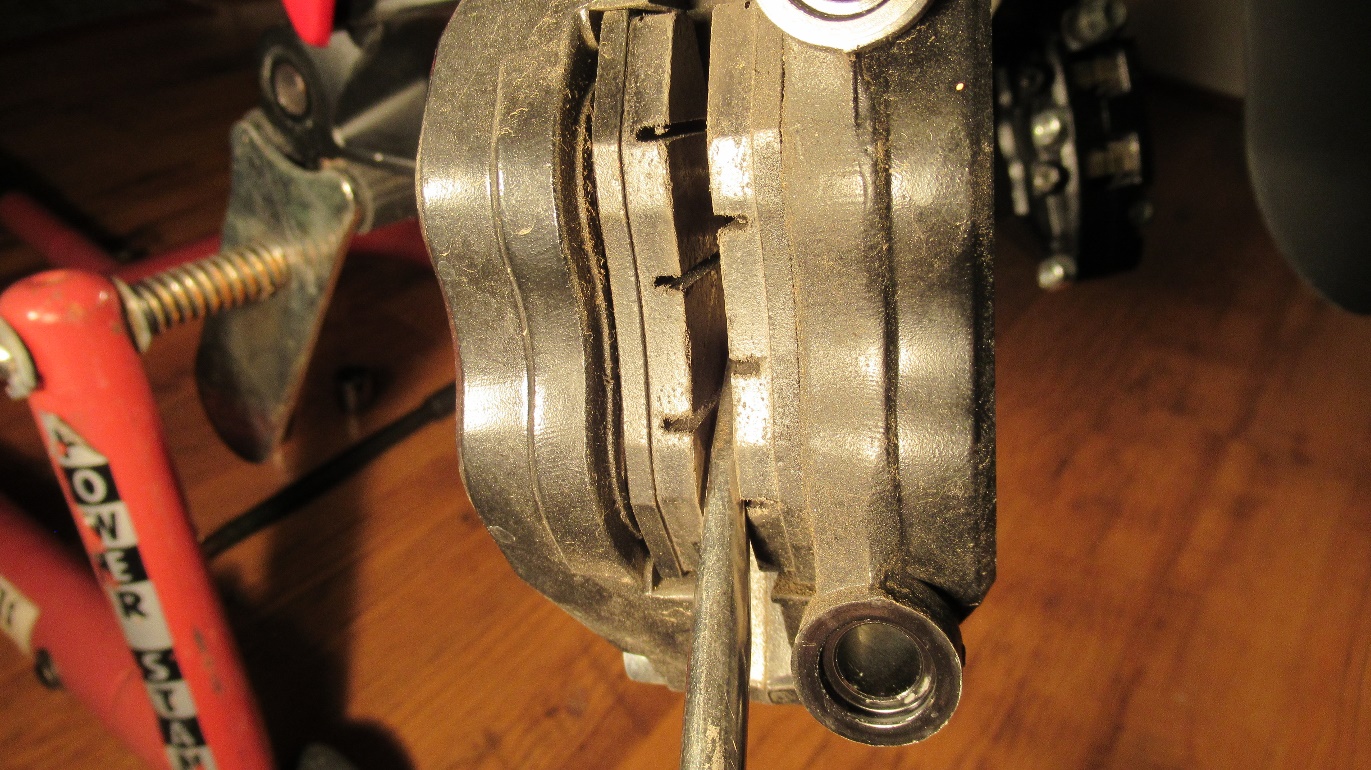

Step 4: With a clean large flat screwdriver spread the brake pads completely apart. This will compress the pistons to make room for the new pads.

Step 5: Remove the brake pad pins and pads

Step 8: Verify caliper locating dowels are in place

Step 6: When installing new pads:

- Do not contaminate pads with grease or oil

- Push pads against the retainer springs and install pad pins

- Verify pads are parallel in the caliper

- Torque caliper bolts to 30 nm (22 ft lbs) (use medium strength thread locker)

- Flush and bleed brake fluid

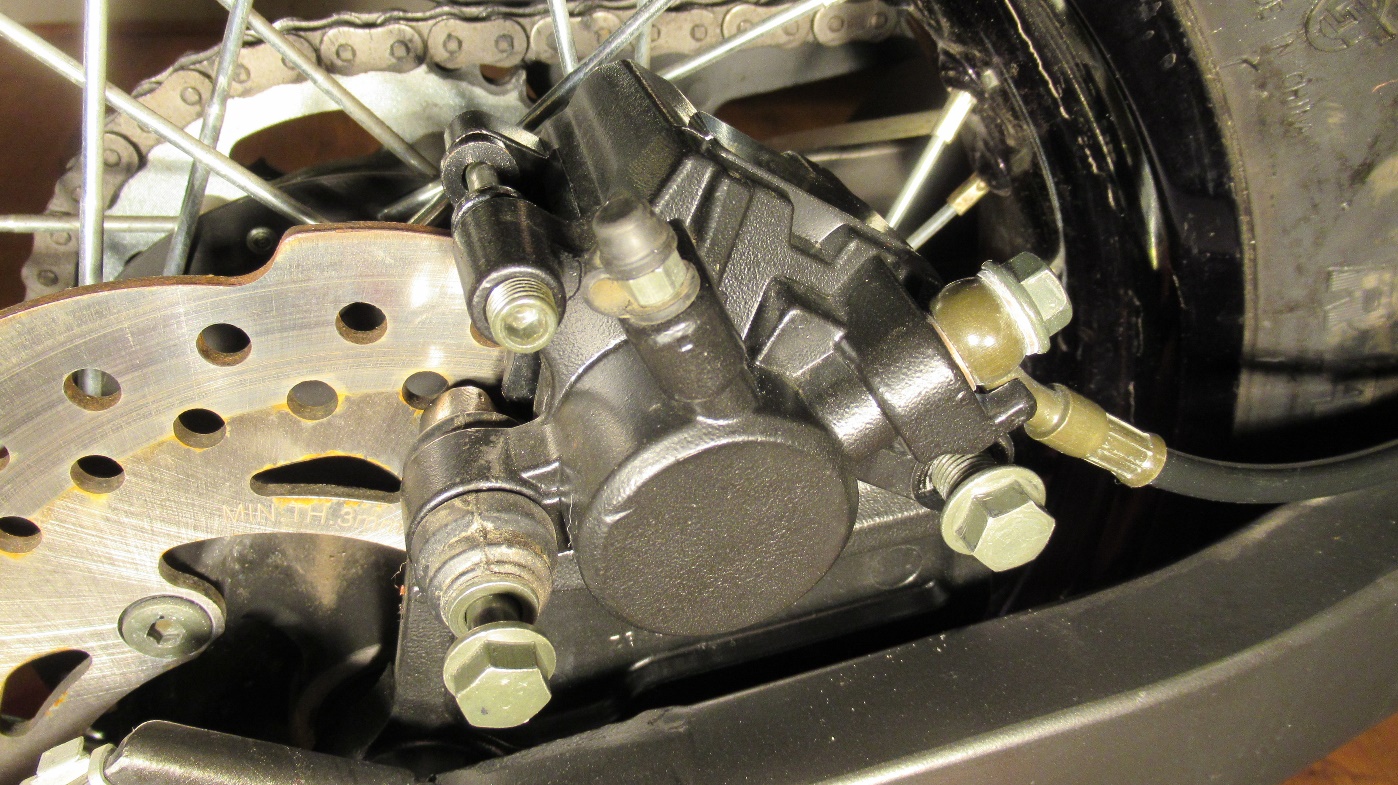

Replacing Rear Pads

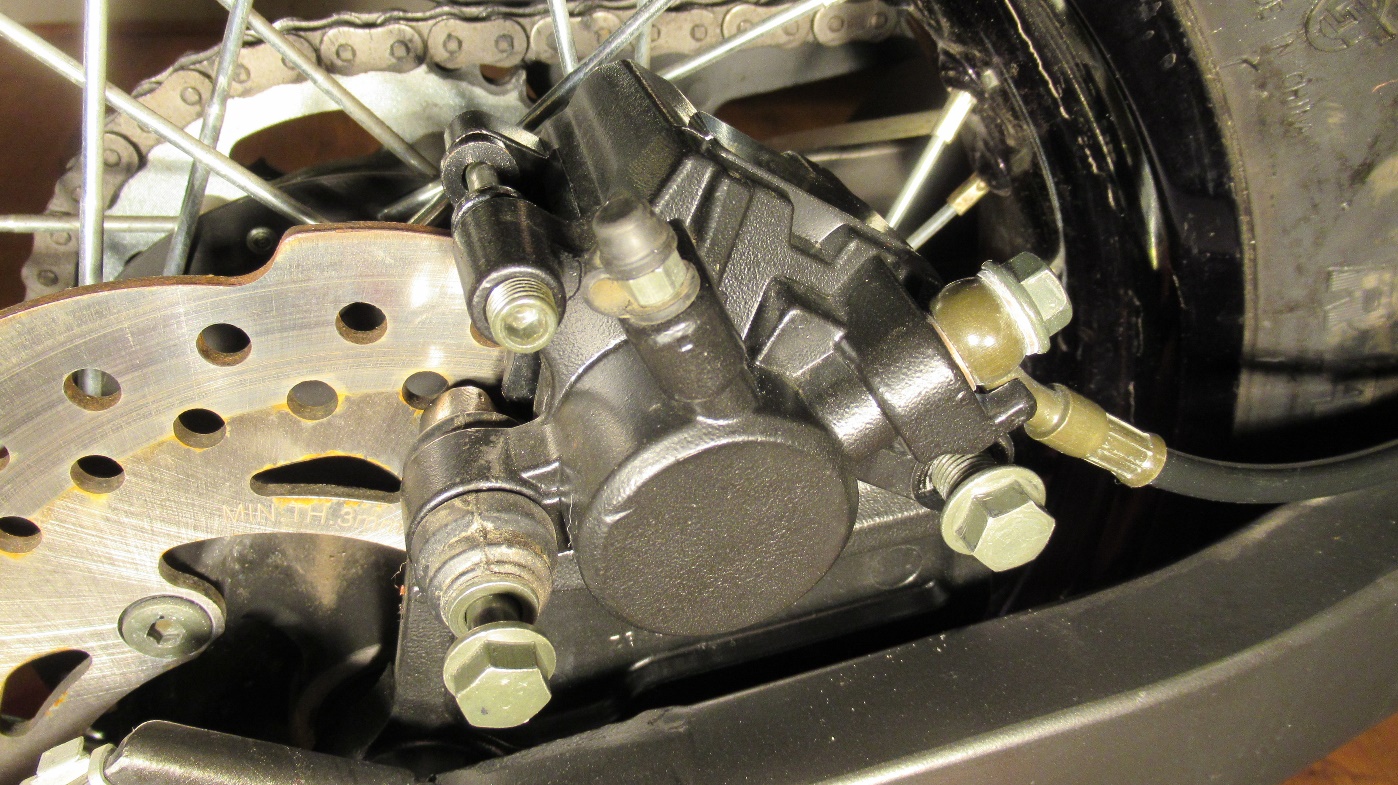

Step 1: Place motorcycle on suitable work stand

Step 2: Remove rear caliper mounting bolts and remove caliper

Step 3: With a clean large flat screwdriver spread the brake pads completely apart. This will compress the pistons to make room for the new pads.

Step 4: Remove the brake pad pin cover, pad pin and pads

Step 5: Install new pads in retaining slot on carrier

Step 6: Install caliper over pads and line up mounting bolts. Install front bolt first. Install rear bolt then pad pin.

Step 7: When installing new pads

- Do not contaminate pads with grease or oil

- Torque caliper bolts to 30 nm (22 ft lbs) (use medium strength thread locker)

- Verify pads are in retaining slot on carrier

- Flush and bleed brake fluid